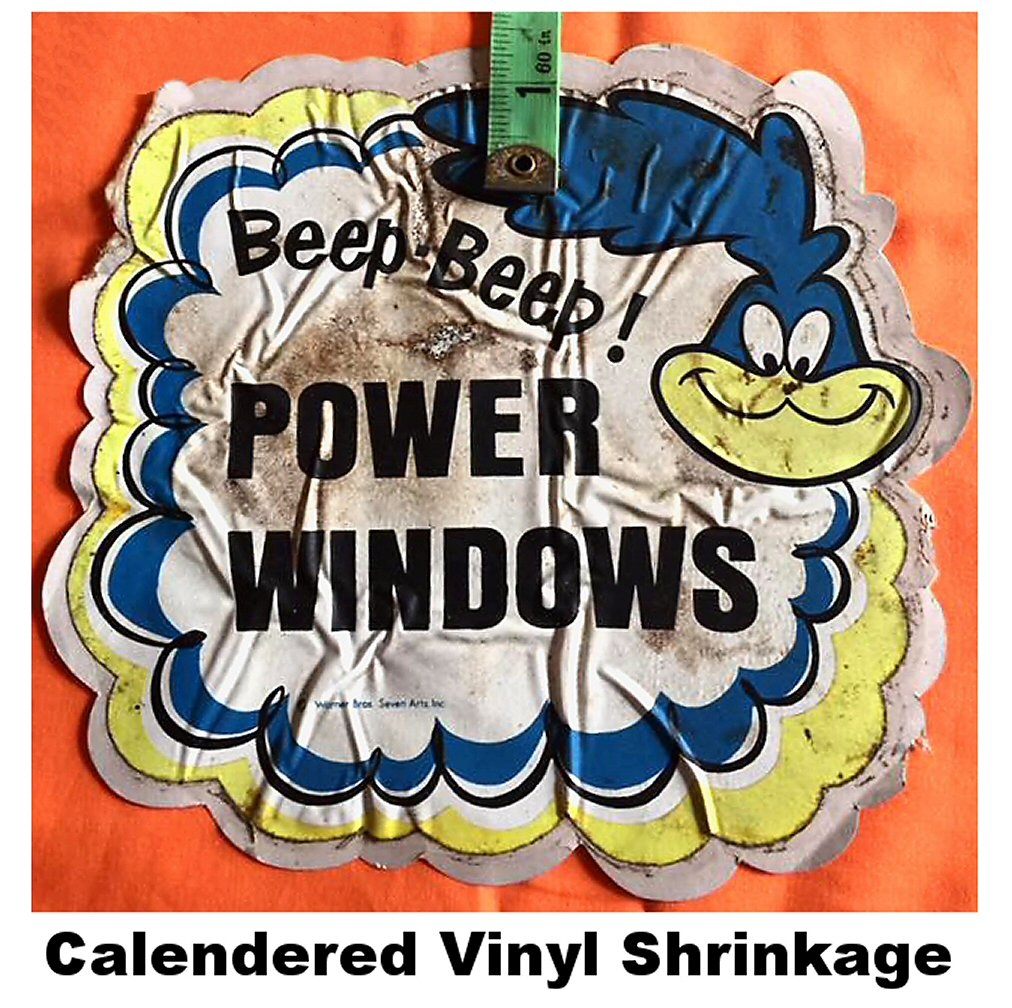

meaning that a large ball of vinyl is squeezed through

progressively higher pressure rollers until it is 4 mil thick.

This method causes the vinyl to have a “memory”, and it

will always, even when applied to the car, want to shrink

inwards towards the center.

Correct vinyl 40 years ago, and today, is “cast” material.

The vinyl is poured into an extremely precise mould,

where it solidifies to 2 mil. There is no memory shrinkage

with cast vinyl. All Premium Commercial-Automotive vinyl

made by 3M is cast vinyl.